We at National Fiber Glass Reinforced Polyester Industries have the pleasure to col-md-6duce our manufacturing facility at Hattar Industrial Estate NWFP and at Green Town Industrial area Lahore.

Our entry in to the Fiber Glass manufacturing is in keeping with our policy of horizontal expansion into related fields and vertical integration of our manufacturing facilities. Sucess in these increasing competitive markets is not achieved without the support of totally dedicated work force which we proudly possess. Our combined experience of over 30 years has enabled us to launch this concern in the forefront of Fiber Glass lamination, designing process, sales and marketing, to sufficiently meet all the present and future needs of the market, we are constantly alert and ever ready to meet the demands of the future.

Fiber Glass is a material which is used by a wide spectrum of Industries, for its strength, insulation and durability, simply because of its light weight, high strength, dimensional stability, chemical and electrical resistance and ease of fabrication. Fiber Glass can be moulded to close tolerance, is rust free and resist heat, cold, moisture and fatigue. Similarly, resistance to ultra violet light and fire can be enhanced by additives and special coatings, if and when required. Fiber Glass products are now common place in transportation becasue of its lower cost of too long compared to steel, and in construction, electical appliances, business machines and also in agriculture, recreational and marine industries.

When it comes turning creative architectural designs into a reality, call in National Fiber Glass Industries. After all it can be the leader in GRP technology and has designed and manufactured many primary structure for architect and developers.

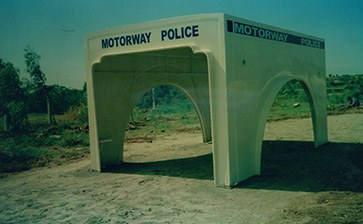

GRP as a structural and decorative material has no equal its outstanding strength to weight ratio, long life durability and almost limitless versatility allows the creation of virtually and shape in an infinite choice of colors and textures. For this reasons, GRP has today been specified for wide range of diverse architectural application including minarets, domes, spires, towers roof system and structures, walk ways, full exterior and interior cladding schemes, faces and canopies.

National Fiber Glass Industries has pioneered in new moulding techniques in meeting client's specific requirement and has invested heavily in new technology in the company's purpose - built, modern factory. through an extensive design, prototyping and pattern making capabilities, has develop specific solution to a wide range of requirements and application.

Nationa Fiber Glass is equipped to mould purpose designed components or to batch produce for phased delivery. Our specially equipped lamination facilities enable us to ensure long life durability in accordance with international standards.

GRP is light weight, noncorrosive, fire retorted, vandal resistant and cost effective and because GRP components and structure are made in the factory under strict quality control procedures, they are designed to be easily transported to site and erected quickly, without the irritating and costly advice for architects. National Fiber Glass Industries has developed a range of standards, but flexible, GRP building system and roof structure for a wide range of application.

National Fiber Glass Industries corrugated sheet system provides economic and permanent building of considerable versatility for sport halls, covered stores, workshop, warehouses, public and private swimming pools etc…., without the need for elaborated foundation, structural sub-frames sports or additional internal linings. The system can be manufactured in any color, fully translucent, opaque, with either a single or double skin, insulted or non-insulated sections as required.

The system is capable of being fitted with a wide variety of optional extra including double and single door modules, fans unit or forced ventilation. The complete system offers a high degree of components standardization, is corrosion free, vandal resistant and simple enough to erect.

Roofing system is an all GRP structure and requires an additional subframe. Each roof section is manufactured to the required length and is designed to be simply bolted together on site in only a matter of day.

If you’re therefore, have a project which would be difficult or unacceptably costly to realize using other materials, call National Fiber Glass Industries, our experienced technical representatives are available for on the spot consultation anywhere, every contract is handled from the outset by an experience supervisor, and if required, even give on site supervision to the contractors owned labor force. National Fiber Glass Industries can design and produce products according to your imagination.